(Un)Wrapping Innovation! The Tool Farmers Can’t Stop Talking About Hits the Big Stage

Wrap Twine Remover (WTR)

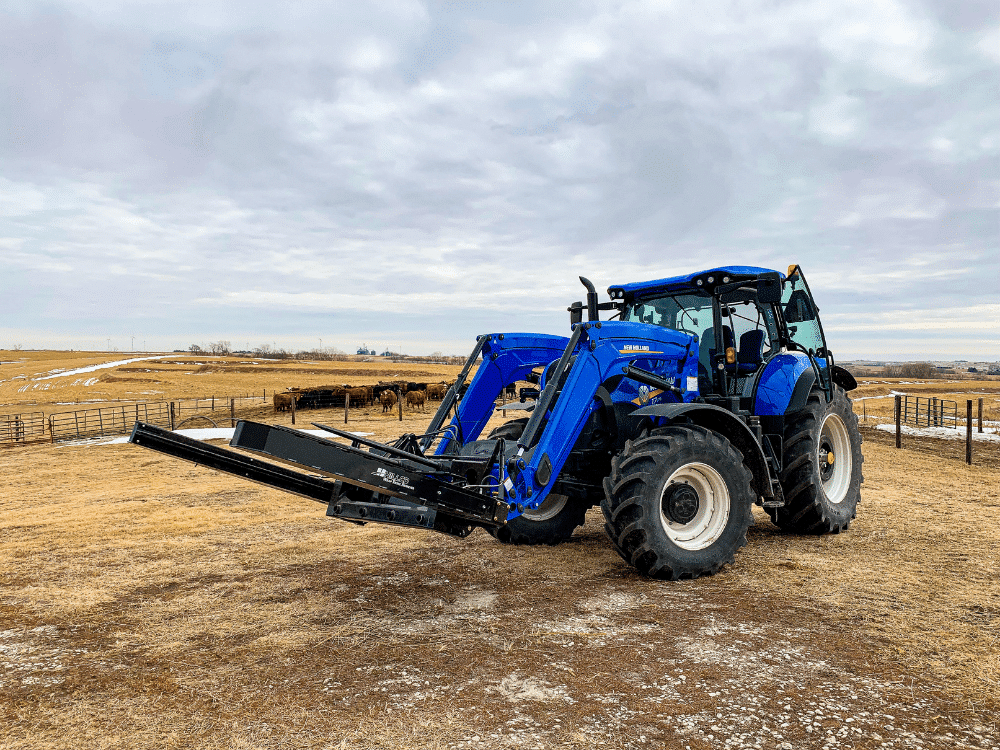

At Hillco Technologies, we’re passionate about creating innovative solutions that simplify life for farmers and ranchers. That’s why we’re thrilled to share that our Wrap Twine Remover has been making waves in the industry! Recently featured in Working Ranch Magazine and showcased on the Facebook page of Feedlot Magazine, this revolutionary tool is gaining attention for its ability to save time and reduce frustration on the farm.

Why the Wrap Twine Remover Stands Out

Twine buildup on feeding equipment is a common challenge that costs valuable time and can cause costly equipment wear. The Hillco Wrap Twine Remover makes removing twine quick and easy, helping you stay productive while extending the life of your equipment. Designed with durability and efficiency in mind, this tool is a must-have for any farm or ranch.

But don’t just take our word for it! The buzz around this innovative tool is growing, and industry experts are noticing. Being featured in Working Ranch magazine and highlighted on Feedlot magazine’s Facebook page shows just how impactful this solution can be for hardworking farmers and ranchers like you.

Feedlot has also published multiple articles on the Wrap Twine Remover, one of which was in 2023.

See It in Person at the Spokane Ag Expo

Curious about how the Wrap Twine Remover works? You’re in luck! We’ll have one of our newest models on display at the Spokane Ag Expo from February 4th to 6th, 2025. Visit us at Booth O42 to see this game-changing tool up close and learn how it can make a difference on your operation.

Talk to Our Team at Upcoming Trade Shows

If you can’t make it to Spokane, don’t worry—we’ll be at two additional trade shows this February:

- Iowa Ag Expo: February 4th-6th, Booth 4005 in Des Moines, Iowa

- National Farm Machinery Show: February 12th-15th, Booth 7562 in Louisville, Kentucky

At both shows, our Hillco team will be available to answer your questions, and help you find solutions tailored to your unique needs.

Why Farmers and Ranchers Love Hillco

At Hillco Technologies, we understand the challenges you face in the field. Our products, like the Wrap Twine Remover, are designed to solve real problems and make your daily tasks more efficient. By investing in the right tools, you can save time, protect your investments from your equipment to you cattle, and focus on what truly matters—running a successful operation.

Learn More Today

Don’t miss your chance to see the Wrap Twine Remover in person! Visit us at the Spokane Ag Expo, Iowa Ag Expo, or National Farm Machinery Show to experience firsthand why Hillco products are trusted by farmers and ranchers across the country.

For more updates, be sure to follow Hillco Technologies on social media (X, Instagram, and Facebook).

Hillco Technologies: Innovating for the Future of Agriculture.