Transforming Farm Operations with Hillco’s Air Flow System: Customer Testimonials

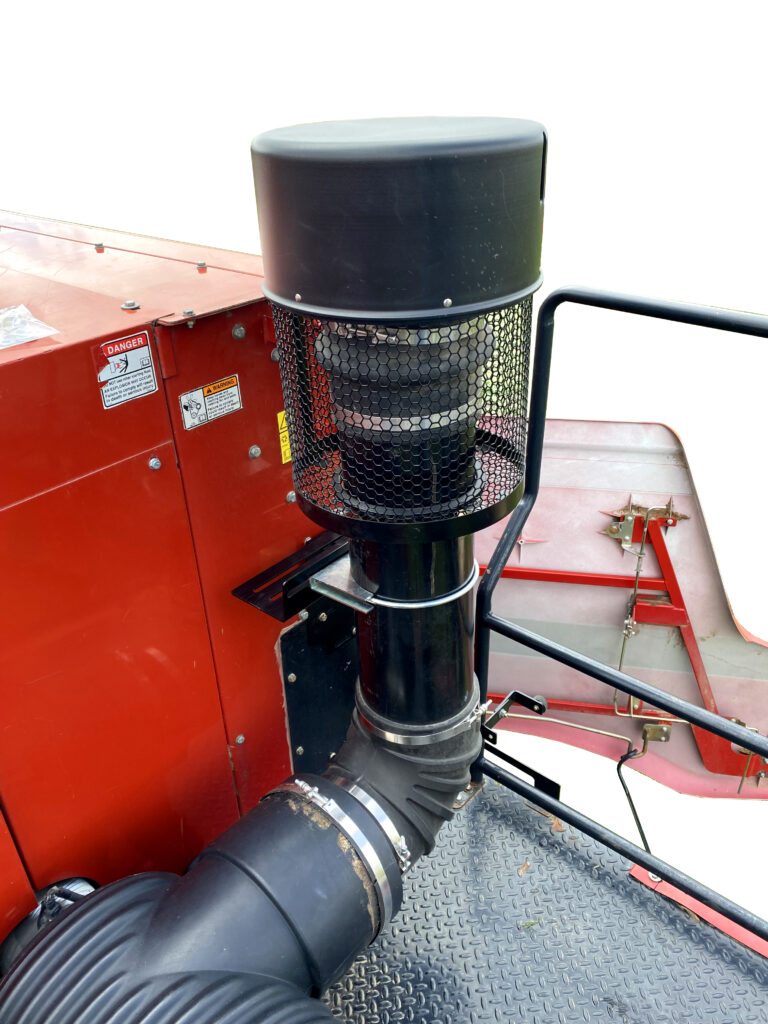

In the agriculture industry, maintaining equipment and ensuring its optimal performance is crucial. Hillco Technologies’ Air Flow System has been a revolutionary product for many farmers, significantly reducing downtime and increasing productivity. Here’s a collection of recent customer testimonials highlighting the impact of this innovative system.

Enhanced Productivity and Reduced Maintenance

Many farmers have experienced a notable increase in productivity thanks to Hillco’s Air Flow System. This system helps keep air filters cleaner for longer periods, reducing the need for frequent maintenance and allowing more continuous operation.

- “We don’t have to stop and blow the air filter out during the day anymore.”

This simple yet powerful statement underscores how the Hillco Air Flow System minimizes interruptions, allowing farmers to focus on their work without the constant need to clean air filters.

- “It has increased our productivity, because we do not have to blow out the air filter every day. Works Great.”

The reduction in daily maintenance tasks directly translates to more time spent on productive activities, enhancing overall efficiency on the farm.

Improved Air Filter Longevity

Farmers have also noted significant improvements in the lifespan and efficiency of their air filters, further reducing the time and effort spent on maintenance.

- “Greatly improved. Went from some days of combining beans and not even making the full day before the air filter was plugged to 2-4 days before I needed to clean the filter.”

The extended periods between necessary cleanings mean fewer interruptions and a smoother workflow.

- “Went from blowing the combine filter out daily to twice a week and it could be just once a week.”

Such testimonials reflect the dramatic improvements in filter performance, which not only save time but also enhance the overall efficiency of farming operations.

Seamless Integration and High Quality

The Hillco Air Flow System is praised not only for its functional benefits but also for its high quality and ease of installation.

- “We put the Hillco system on our Magnum 340. During planting season, we had no downtime or wasted time servicing the air cleaner. Fit and finish of the product is excellent and easy installation. 10 out of 10 for us!”

This testimonial highlights the ease with which the system can be integrated into existing machinery, its durable construction, and the substantial operational benefits it provides.

Hillco Technologies’ Air Flow System has proven to be a vital addition to many farming operations. By significantly reducing the frequency of air filter maintenance, it allows farmers to spend more time on essential tasks and less time on equipment upkeep. The positive feedback from users underscores the system’s effectiveness and value, making it a worthwhile investment for any modern farm looking to boost productivity and efficiency.