The Rancher’s Plight: Plastic Disease in the Herd

The danger of plastic ingestion by cattle, specifically the risks associated with net wrapped hay bales, cannot be overstated. This condition, otherwise known as “plastic disease,” causes severe health issues and even death in cattle. The most effective means of avoiding these losses in the herd is by removing net wrap before feeding.

Introduction

A rancher knows that cattle are hasty eaters and curious to-boot. This frequently leads to ingesting foreign objects. The result has been termed “hardware disease” from ingesting metal objects. A similar condition is caused by ingesting plastic materials like net wrap. Net wrap ingestion can block the flow of nutrients in the rumen, leading to severe health problems and potentially fatal outcomes.

Health Risks

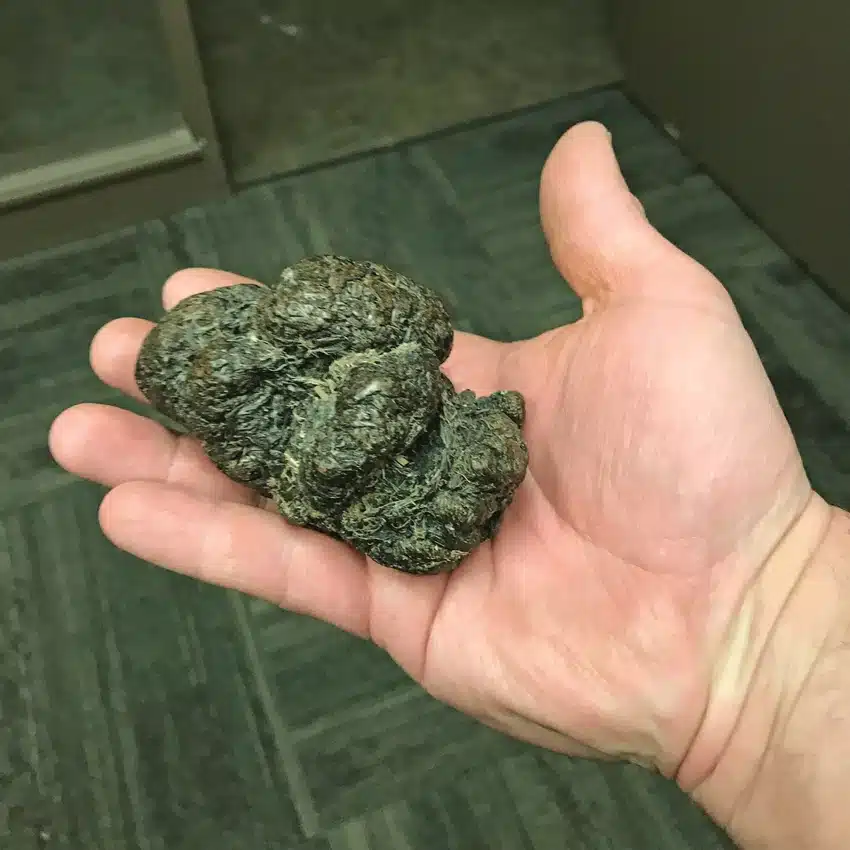

When cows ingest net wrap, it can become compacted into hard masses or remain in its original form.

Regardless of its form, its presence obstructs nutrient flow because bacteria in the rumen cannot break down plastic. These obstructions can cause severe digestive issues, malnutrition, and even fatal bloating. In the vent that this compaction blocks the esophagus, it prevents the cow from belching resulting in a buildup of gas.

Case Studies

A Veterinarians’ Observation:

- Cody Creelman, a veterinarian, recounted a case where a producer experienced high rates of free-gas bloating in cows due to net wrap ingestion. With the death-count at seven cows, post-mortem examinations were necessary. This investigation revealed plastic masses in their esophagi.

- This producer’s conclusion was that he needed to remove the net wrap before feeding, effectively resolving the problem.

A Veterinarian’s Investigation:

- Veterinarian John Campbell investigated the deaths of six cows from a well-managed herd. It was discovered that theses cows were close to calving and died due to large amounts of net wrap occluding the rumen outflow. Ultimately, it was this professional’s opinion that the combination of a full rumen and large uterus suffocated the cows by putting excessive pressure on their lungs.

- Campbell observed that net wrap can create blockages at the exit into the intestine, causing malnutrition and a slow and persistent decline in health.

Preventative Measures

- It is apparent that removing net wrap before feeding is crucial. Producers should cut off the net wrap or twine from bales, even if it requires extra effort, especially in cold conditions where the wrap may freeze to the bale.

- Our solution to this obstacle is Hillco’s Wrap Twine Remover. The Wrap Twine Remover (WTR) from Hillco Technologies is an attachment that removes twine and net wrap from large round bales or large square bales, quickly and efficiently, without the operator ever leaving their seat. The WTR does not cut the bale in half and allows the bale to be placed directly into the feeder or tub grinder without being destroyed prior to placement. The “squeeze” function allows the operator to reposition or relocated the bale in mid-operation to another feeder without losing the entire bale.

- Some producers drop the bale on the ground from a loader, causing additional hay loss, to help break loose the wrap. However, this step helps them ensure no hazardous remnants are left for cattle to ingest.

Other Sources of Plastic & Foreign Objects

- Cattle may ingest other foreign materials like twine, plastic bags, and garbage, when hay is baled near roads or littered areas. These objects form large masses in the rumen, with results comparable to net wrap occlusions.

- Even small amounts of plastic can cause significant issues, leading to partial blockages and symptoms like diarrhea.

- These symptoms are often mistaken for diseases.

Conclusion

- Ingesting net wrap and other plastics is a growing concern for cattle health, with the potential to cause severe, often fatal, digestive issues.

- Ranchers and producers must be diligent in net wrap removal before feeding in light of these health risks. The cost and effort spent in removing net wrap are minor compared to the potential loss of cattle and associated veterinary expenses.

Source: Beef Magazine