Pivoting Spout: Comparison

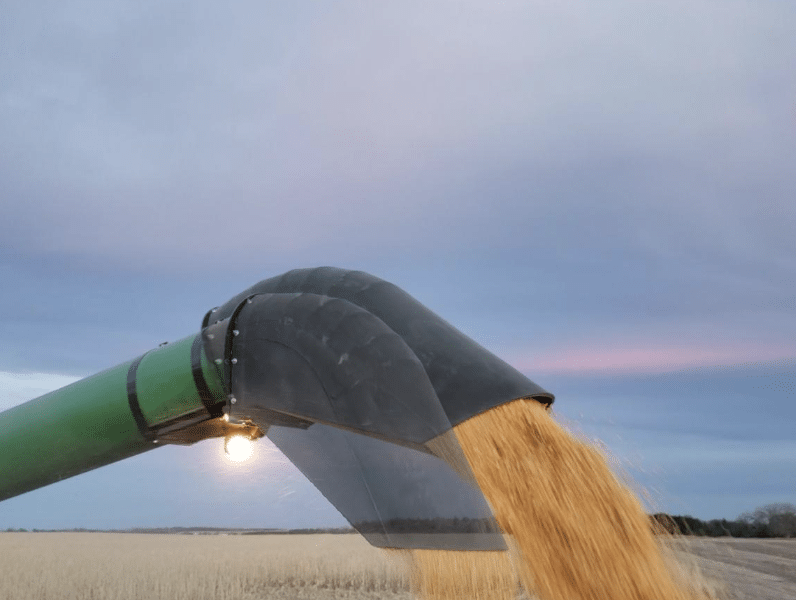

Adjustable auger spouts serve an irreputable purpose in the process of grain loading. With their growing popularity, additional manufacturers are entering the market. For anyone debating the pros and cons of one manufacturer’s design over another, we have taken an in-depth look into the similarities and differences between other spouts and our own.

The Similarities Likenesses Parallels

- They utilize electrical linear actuators.

- They will work on the 17-inch High Unload Rate Augers.

- They are available for John Deere combines.

- Comparable shipping weights at 120lbs each.

The Differences Contrasts Variances

- In addition to providing pivoting spouts for John Deere combines, we are in the process of releasing our Case IH model for combines equipped with 14-inch augers.

- At an increase of 56%, other manufacturers have set a price point that is more than double ours.

- Whereas other adjustable grain spouts have actuators that are under the spout, presenting a risk of getting hit, Hillco has placed it securely behind the spout for protection from impact.

- Other spouts must be purchased through a dealer. Hillco has a focus on customer convenience, which is why we sell directly to customers in addition to partnering with dealers.

- When turned off, other spout boots automatically move with the goal of preventing grain from spilling out the end of the auger. When the unload switch is activated, this boot lowers to empty grain and then raises to provide clearance. This is accomplished through integrated electrical connections, or CAN bus connections. These CAN bus connections allow for the spout to return to an upright (storage) position when not in use. It is then activated when the unloading auger button on the propulsion handle is pressed. It is still controlled with a foot switch for articulation.

- While this can be a benefit for using OEM switches and catching grain dribble, troubleshooting can be a challenge. As an integrated design, tracing the source of issues is likely challenging for customers and technicians not well-acquainted with the product.

- Another potential issue is that by lowering the spout when not positioned correctly, it could contact the edge of a grain cart.

- Also, in a similar situation, it could guide flow in a way that will overfill the truck or cart in that direction. The operator can override it, but they would have to be cognizant of this upon shut off, after which the spout no longer returns to the ‘home’ position.

- On the Hillco Pivoting Spout, when the button is pressed, we rely on the OEM grain dripple door to halt flow and our spout remains in position. The foot switch must be activated to raise it. We do not integrate, which makes ours a stand-alone system. A stand-alone system means easy diagnostics. Also, if the end user wishes to update their combine, the spout can be moved to their new machine quickly and with minimal difficulty.

- Other pivoting spouts must connect into power at the battery and into the AUX power strip located in the cab, whereas we only require connection at the battery.

- Other versions of the pivoting spout have foot pedals with a two-pedal switch. In that set up the operator must move their toe from left to right. Comparatively, we use a rocker style foot pedal. This style allows you to adjust your foot pressure to the left or right without needing to move your foot.

Facebook

Twitter

LinkedIn