Maximizing Efficiency in Cattle Feeding Operations: The Importance of Hillco’s Wrap Twine Remover

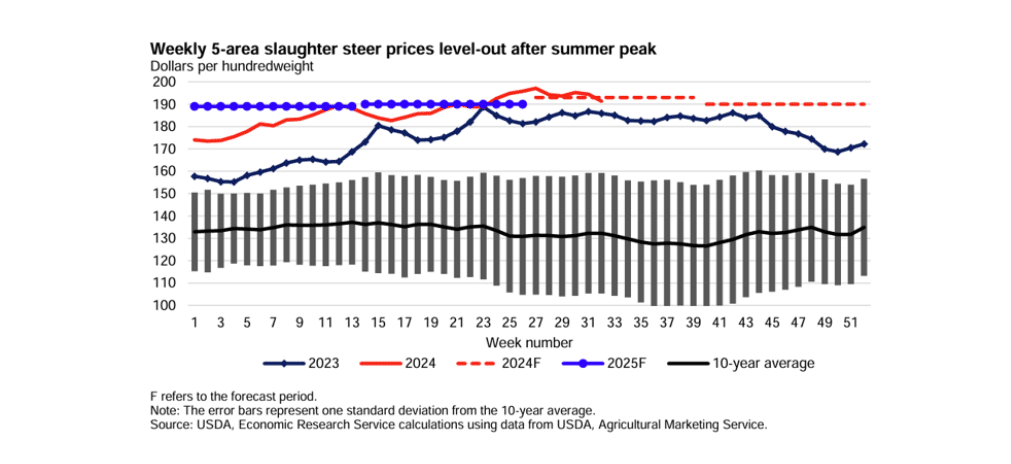

As cattle prices rise, efficient operations are crucial for profitability. In July, the average price for feeder steers at the Oklahoma City National Stockyards was $263.06 per hundredweight (cwt), nearly $19 higher than the previous year. Slaughter steer prices in the 5-area marketing regions identified by the USDA to track and report cattle prices (such as Texas, Kansas, Nebraska, Colorado, and Iowa) averaged $194.82 per cwt, up $11 year-over-year, with projections showing continued strength into 2025. This recent data highlights the strength in the market, with slaughter steer prices projected to increase steadily through 2025. In such a climate, every aspect of cattle feeding must run smoothly.

The WTR (Wrap Twine Remover)

One potentially overlooked but essential tool in maintaining feeding efficiency is the Wrap Twine Remover (WTR) from Hillco Technologies. Designed to prevent twine and net wrap from clogging machinery and out of cow’s stomachs, this product ensures that hay processing equipment operates without costly downtime. In addition to the increase in safety attained when the operator doesn’t have to wade through ravenous cattle, crawl in and out of tractors, or teeter precariously over tub grinders in mud and icy conditions, all these events require more time. When you are multiplying that single event by a few thousand, the time lost at each feeding makes a serious impact on production and, ultimately, profit.

During the hay season, when feed quality and availability directly impact cattle growth and market readiness, uninterrupted machinery function is vital. Clogged hay equipment can lead to delays, reduced feed quality, and ultimately, lower weight gains for cattle. Additionally, plastic disease in the herd can severely impact profits (INTERNAL LINK). The Wrap Twine Remover addresses this issue by simplifying and accelerating the removal of twine and net wrap, which can accumulate around equipment parts.

As the Wrap Twine Remover supports higher production levels, it enables farmers to match the current upward trend of rising cattle prices, making it a smart choice for any operation looking to maximize efficiency and profitability in a competitive market.

Investing in innovative tools like the Wrap Twine Remover also supports operations in achieving higher productivity. As prices are projected to rise, efficient and consistent feed processing becomes even more critical for maximizing the potential of your cattle. Social media influencer 1HandnFarming uses our WTR in his daily feeding operations. He says Hillco’s WTR makes removing net wrap easy and commends the safety of not having to get out of the cab. Additionally, he’s challenged others removing netwrap and twine with a knife to try beating the WTR in a speed test at 10,000 bales.