Maximize Your Harvest: How Hillco Leveling Systems Improve Productivity & Grain Savings on Hills

The Hillco Leveling System Advantage

Farming in the hills presents unique challenges and one of the most difficult is harvesting. The farmer works all year planting and growing his crop with a focus on maximizing yield and minimizing costs while maintaining the quality of his farmland. But come harvesting time, he must fight the hills in an effort to save the grain he’s spent the year growing while maintaining as much of the combine’s productivity as possible to fit harvest into an ever-smaller harvest window. The best

way to ensure you save the grain and maximize your combines productivity is by equipping your combine with a leveling system from Hillco Technologies.

The advantage of a Hillco equipped combine is found in this simple formula:

Increased Grain Savings + Increased Productivity – Cost of Ownership = Maximum ROI

1. Increased Grain Savings

Today’s combines are not designed to function well on slopes. There have been millions of dollars and decades of time spent trying to improve the performance of level land combines in the hills. Yes, they’ve improved, but they still lose significant amounts of grain while harvesting on slopes. Unless you already have a Hillco Leveling System on your combine, you know they do because you can see it on your combine’s grain loss monitor. The steeper the hill, the more the grain loss. It does not take much slope, in heavy yielding grain, to put your monitor in the red. With a Hillco installed, your combine stays level in the hills, optimizing the performance of your combine’s cleaning system, saving the crop you have worked all year to grow. It takes a surprisingly small amount of grain loss (2bu/a on 1500 acres) to add up to $10k or more of lost income.

2. Increased Productivity

When you’re in the hills harvesting with a level land combine and the grain loss monitor shows you’re losing grain, the natural response is to slow your harvesting speed. It may help some, but you sacrifice much of the productivity that you paid for in your new combine. Reduced harvesting speeds increase the operating hours on your combine leading to increased fuel, labor and maintenance costs while significantly increasing your combines depreciation and lengthening your harvest season. It’s a Catch 22….do you slow down and save some grain but lose productivity or do you maintain your speed and experience greater grain loss? With a Hillco on your combine there is no more compromise. Save your grain while maintaining peak productivity of your combine and get your crop out of the field on time.

Faster harvest speeds=

✅ Lower fuel costs

✅ Reduced labor expenses

✅ Fewer separator hours, minimizing depreciation

✅ A shorter harvest window, avoiding weather-related losses

3. Cost of Ownership

You don’t get a Hillco on your combine for free so you must consider the cost of equipping your combine with a Hillco to understand the real Leveling System Advantage. There’s an initial investment in the Hillco but

they typically retain 40% of their value after 5 years of use. Add in some annual maintenance costs to keep it in top shape and performing.

Investing in a Hillco Leveling System provides long-term financial benefits:

- Retains 40% value after five years

- Annual maintenance costs as low as $1,680

- Maximize your Return On Investment

4. Return on Investment

Hillco has created a Return On Investment (ROI) Calculator as well as detailed explanation to

bring together all the benefits and costs discussed and presented it in a simple form. For this detailed summary, visit our page on Hillco Leveling Systems. In the short term here’s another common example of the ROI we see regularly with our customers who harvest in the hills.

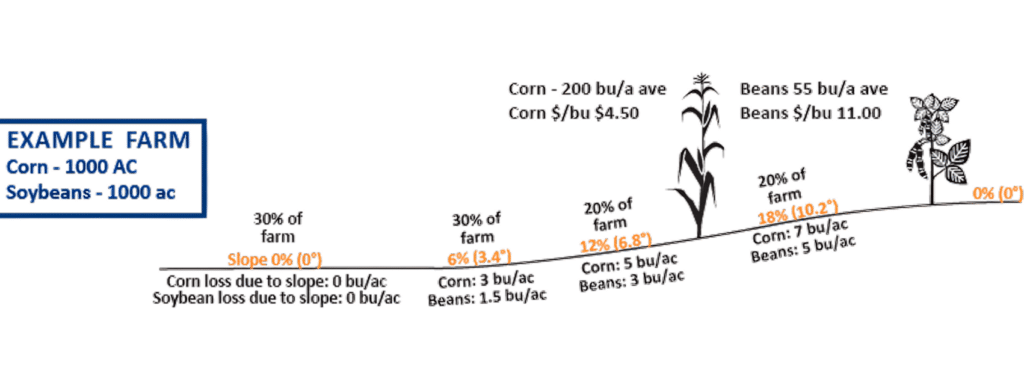

A farmer whose Annual Acres Harvested is 2000 acres with one combine will have to make a decision between Grain Loss vs. Harvesting Speed. Though conditions vary substantially with many factors such as yield, moisture content, and variety affecting grain losses, a common average of those losses on the different slope range, can be determined. We have found a reasonably close correlation between harvesting speed and grain loss. If you halve the speed, you halve the loss. The calculator computes the grain loss based on the harvesting speeds you choose for each slope range and a grower in this scenario typically sees a grain savings of ~$38,500 over a two-year period.

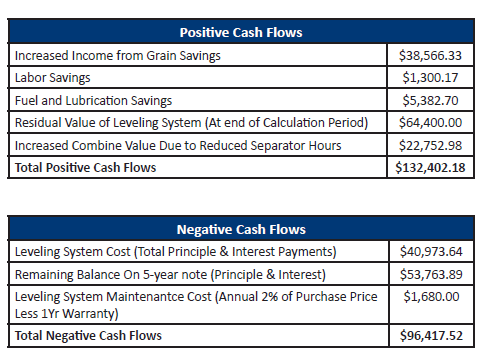

In this same timeframe, they could see a productivity increase through less labor, fuel, combine separator hours, and increased residual value to have a total positive cash flow of ~$93,000k.

This brings the total Grain Savings + Productivity Savings to a total of ~$132,000k.

A Hillco Sidehill leveling system currently sells for ~$84,000 and the resale value of $35k after 5 years, input any annual interest rate if financing the combine, we used a rate of 7%. Calculate labor, fuel and separator hours cost and total these numbers. The annual maintenance cost on a leveling system is ~$1680/yr after two years of operation and is included in the calculator. In this scenario the farmers’ two-year cost of ownership is about $96,000k

Increased Grain Savings + Increased Productivity – Cost of Ownership = The Leveling System Advantage

($38,500) ($93,000) (-96,000) ($35.5K over 2 years)

Return on Investment – By inputting his information into the ROI calculator the farmer in this example not only sees an ROI of ~$35k, but there is also a Payback Period, or amount of time it takes for an investment to pay for itself, of 4.67 Years with an internal rate of return of 29%.

We understand not every farm is the same, and many variables affect your ROI, for example, if you cut grain losses in half across the slope ranges it will increase the average payback period to 10 years and the internal rate of return to 18%. We encourage you to take some time and utilize our ROI calculator so you can see what a Hillco can do for your farming operation. Try the ROI Calculator for your operation.

Additional Benefits of Hillco Leveling Systems

✔ Cleaner Grain Sample – Reduces dockage with a level combine

✔ Increased Stability – Prevents grain sluffing and sliding on steep slopes

✔ Enhanced Operator Comfort – Reduces fatigue from working on uneven terrain

✔ Near-Factory & Dealer Installation – Seamless integration with John Deere & Case IH

Increased Combine Cleaning Capacity – Cleaning capacity is limited to the surface area of the sieves and how level the shoe is maintained. On a slope, as gravity moves the crop to the low side of the combine, the cleaning capacity is reduced but not until 18 or 28% percent with a Hillco Leveler

Cleaner Grain Sample – a level combine directs the air flow and distributes grain from the rotor evenly across the cleaning shoe. This results in less material other than grain in the bulk tank. A cleaner tank results in less dockage when the crop is sold.

Increased Stability – Maintaining a level grain tank lowers the center of gravity; by shifting the weight of the combine uphill, the grain is less likely to sluff, and the combine is less likely to slide. This allows for more time in the cut before needing to empty the grain tank.

Operator Comfort – Our customers don’t make the leveling system decision based on operator comfort alone, but they tell us it is one of the main reasons they will never operate a level-land combine in the hills again.

Quality & Reliability – Made in the United States, control over the leveling system build, is monitored through each step of the manufacturing phase. From our very first leveler developed in 1992, we have been dedicated to improving our levelers year to year. We value our end user and dealer input and work directly with the OEMs to ensure the product has their stamp of approval.

Installation –

Near Factory Installation: Hillco offers near factory installation service for all new combines. Order a new combine and a Hillco Leveling System and the combine will arrive at your dealership ready for PDI.

Dealer Installation: The unique bolt-on design of Hillco Leveling Systems makes dealer installation a convenient option for both new and used combines.

Warranty – Hillco has warranty agreements with John Deere and Case IH ensuring that the installation of Hillco Leveling Systems does not affect the existing combine warranties. This also guarantees that Hillco has the latest design information about the combines we manufacture leveling systems for so that Hillco Leveling Systems are seamlessly integrated into the combine to create a true sidehill combine.

Product and Customer Support – Hillco stands behind its products and is committed to providing the best service and support available. We provide dealer and end user training and product support to maximize your harvest potential.

It’s tempting in times of low grain prices to consider cutting out unneeded expenditures, but you can see from the returns we’ve shown you above that a Hillco Leveling System enhances your profits year after year. When every penny counts, you can rest assured that a Hillco Leveling System is an important and profitable part of farming in the hills.

Maximize Your Harvest with Hillco

In times of fluctuating grain prices, maximizing yield and efficiency is more important than ever. Investing in a Hillco Leveling System ensures that every bushel counts—helping you harvest more, save more, and profit more year after year.

💡 Calculate your ROI today by clicking the Calculate button bellow!